The Czochralski (CZ) method of crystal growth has been around for a hundred years. It is one of the most productive ways to create high-purity and high-quality single-crystal silicon for semiconductor and solar wafers. Many years ago, these industries made CZ growth the standard for production. CZ grown wafers are the basis for a multitude of solid state electronics used in our everyday life, as well as highly efficient solar cells. The CZ method offers repeatable performance, precise control of intrinsic specifications, and can be scaled to very large operations.

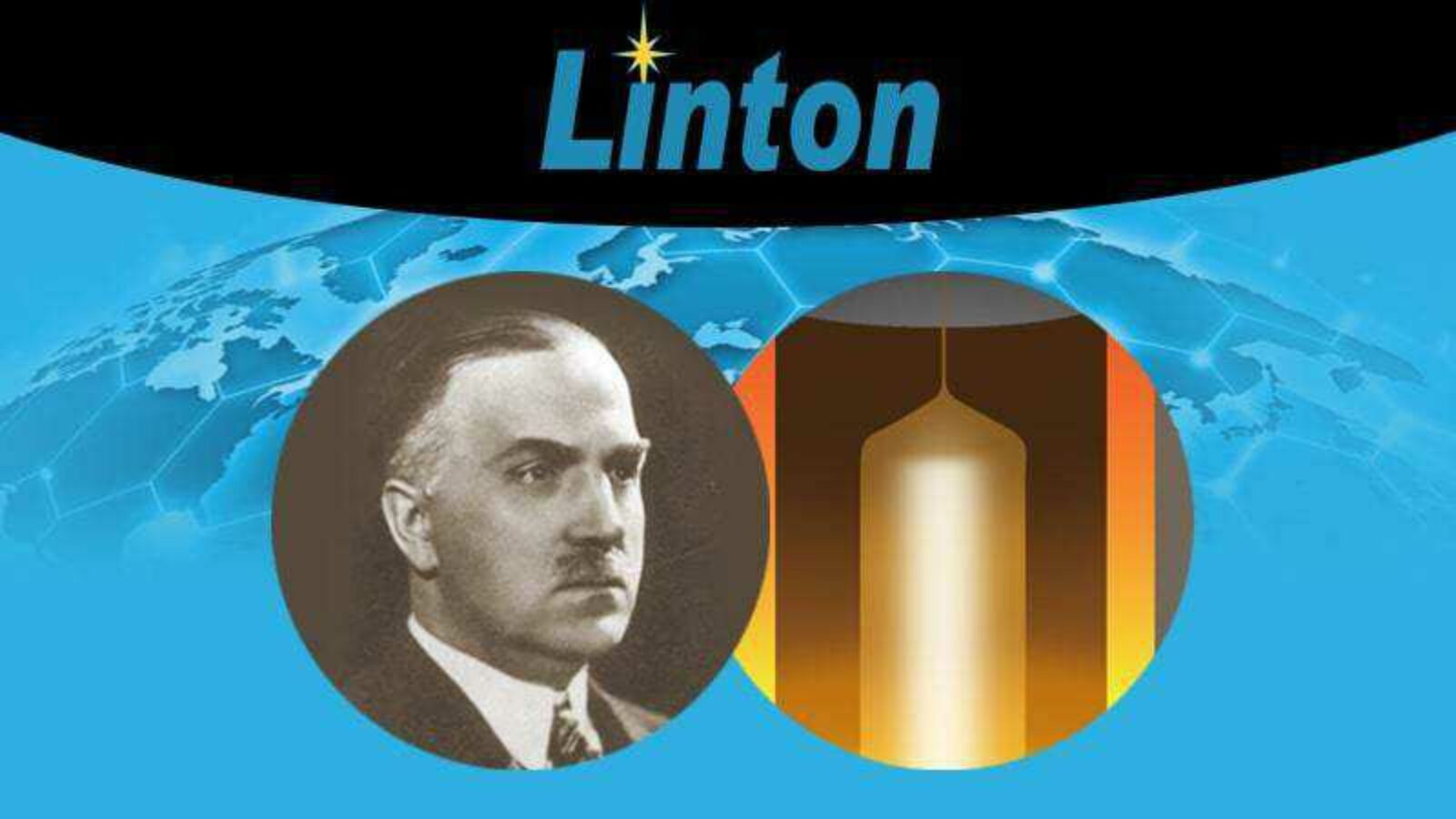

The Czochralski method was discovered accidentally. As with many life-changing inventions (penicillin, the pacemaker, Super glue and Post-it notes among them), this technique was unearthed when its inventor was working on something else. In 1916, Polish chemist Jan Czochralski, then chief of AEG’s metals laboratory in Berlin, was studying the crystallization of metals. He left a crucible of molten tin on his table to slowly cool and crystalize. While writing experiment notes, he absentmindedly dipped his pen in the crucible instead of the nearby inkwell. When he pulled it out of the crucible, he noticed a thin thread of solidified metal hanging from the tip of the pen’s nib. This phenomenon—crystallization by pulling from the surface of a melt—does not occur in nature and his observation of this process proved to be an important discovery. To recognize and celebrate his discovery, Poland designated 2013 the Year of Jan Czochralski.

To grow an ingot for the semiconductor industry using the CZ process, first rocks of “11 nines” purity silicon (99.999999999 percent pure) are placed in a quartz crucible within a specialized vacuum furnace. This is then heated to 1,425 °C (2,597 °F), melting the silicon. A small seed crystal mounted in a fixture at the end of a cable is lowered to touch the surface of the melt. The crucible and the cable holding the seed crystal rotate in opposite directions, and the seed is slowly drawn away from the melt. This allows growth of the cylindrical crystal ingot to the desired diameter and length. The temperature and pull speed are carefully monitored and controlled throughout the growth process to maintain crystal quality and avoid unwanted instabilities or defects. Additionally, the crystal can be either p-type or n-type, with different electronic properties, by adding dopant impurity atoms to the silicon, such as boron or phosphorous.